WQ (D)-S series sewage pump

Category:

Sewage pump

Description:

1. All stainless steel precision casting shell, super corrosion resistance. 2, double end mechanical seal single end mechanical seal, two fluorine rubber mechanical seal effectively improve the electric pump waterproof, corrosion resistance.

Rated flow:

10m³/h

Rated lift:

10m

Rated power:

0.75kw

Rated voltage:

220/380V

Caliber:

60mm

Synchronous speed:

3000r/min

Key words:

Customize your own sewage pump

WQ (D)-S series sewage pump

Conditions of use:

1. Subject to the center of the impeller, the depth of diving into the water is≤5m;

2. The temperature of the conveying medium is not higher than +40° C;

3. The PH value of the conveying medium is 304 (4-10), 316 (2-13);

4. The motion viscosity of the conveying medium≤7x10-7-23x 10-6m2/3/s;

5. Use voltage 220/380V, frequency 50Hz, voltage fluctuation does not exceed 10% of the rated taxi;

6. Electroplating, chemical and other sewage and wastewater containing corrosive media;

7. Prevent the reuse of wastewater from secondary pollution of the overcurrent medium;

8. Sewage containing solid particulate matter, long fiber and other debris;

9. Water supply and drainage in the aquaculture industry.

Features of WQ(D)-S series national standard flange sewage pump:

1. It adopts an ll-stainless steel precision casting shell with super corrosion resistance.

2. Double-end mechanical seal + single-end mechanical seal, two fluorine rubber mechanical seals effectively improve the waterproof and corrosion resistance of the electric pump.

3. F-class insulation grade,≤4kW can be equipped with a thermal protection device to effectively extend the service life of the electric pump.

4. The hot water motor can be customized to solve the use environment of the medium temperature ≤103° C.

5. Special cutting devices can be configured to transport medium conditions containing long fibers, plastics, straws, ropes and other debris.

6. It can be equipped with a mixing device to extract sediment.

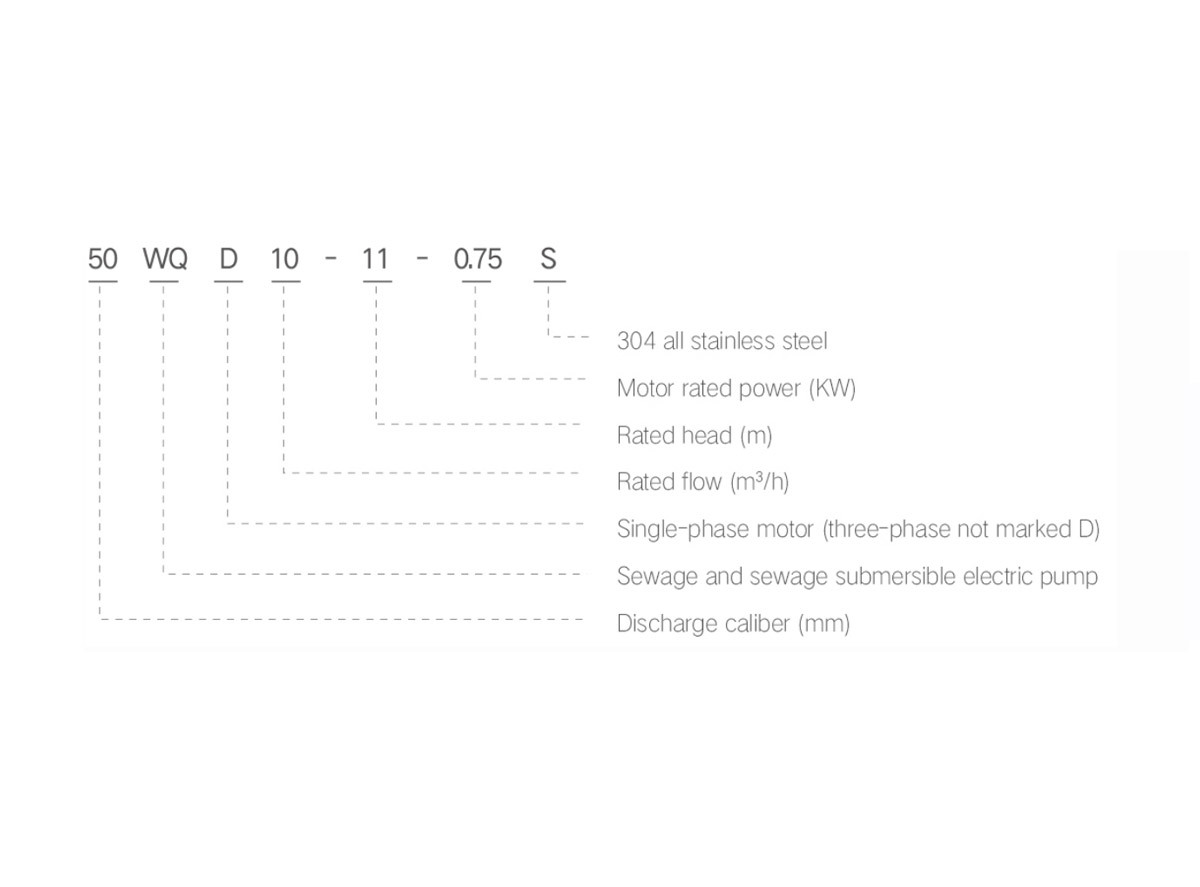

Model Description

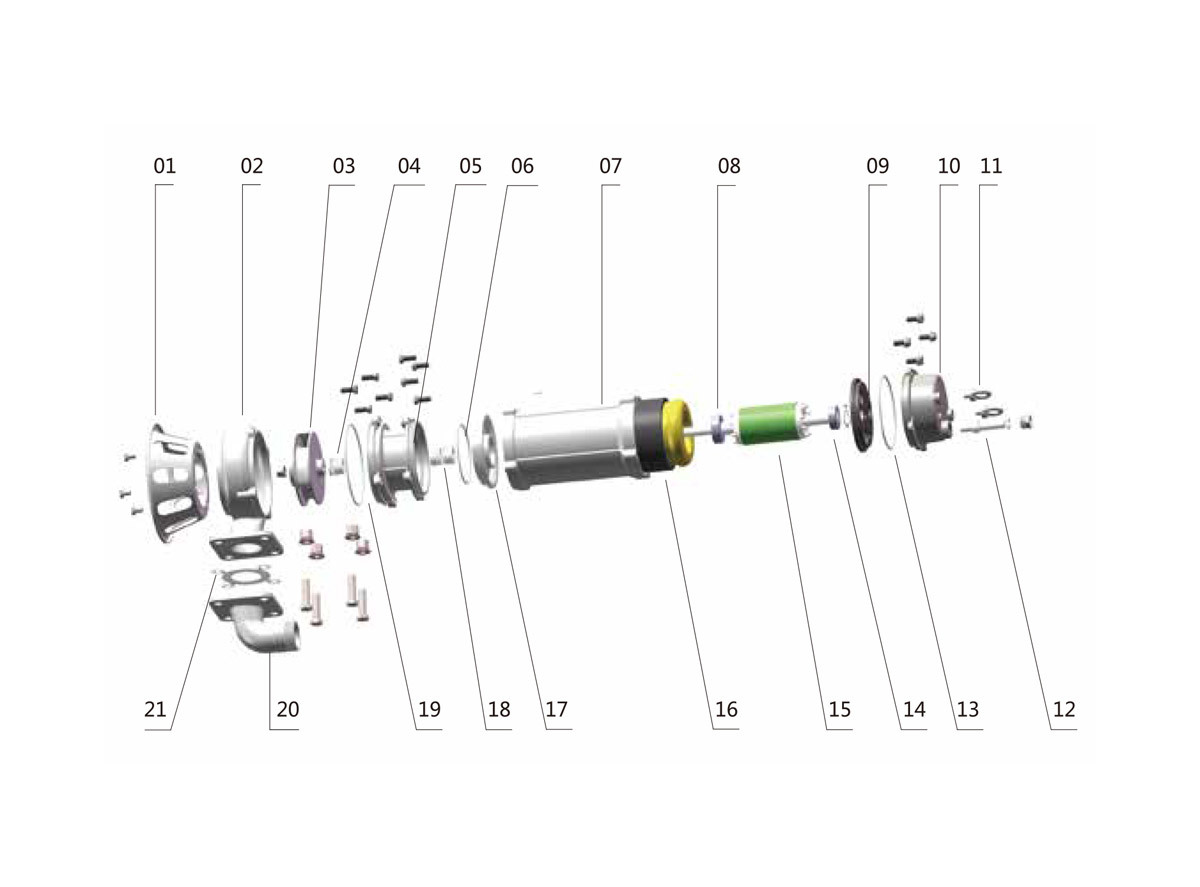

Explosion Chart

WQ Explosion Chart

|

WQ Explosion Chart |

|||||

|

Serial Number |

Component Name |

Serial Number |

Component Name |

Serial Number |

Component Name |

|

01 |

Chassis |

08 |

deep groove ball bearing |

15 |

Rotor |

|

02 |

Pump body |

09 |

Upper bearing seat |

|

stator coil |

|

03 |

Impeller |

|

Top cover |

17 |

Lower bearing seat |

|

04 |

mechanical seal |

|

Lifting ring |

18 |

mechanical seal |

|

05 |

Oil chamber |

12 |

Cable |

19 |

0 type seal |

|

|

0 type seal |

13 |

O-ring |

20 |

Outlet elbow |

|

07 |

Case |

14 |

deep groove ball bearing |

21 |

Flange pad |

WQ(D) technical parameters

| Model |

Rated flow m3/h |

Rated lift m |

Rated power kw |

Voltage V |

Caliber mm |

synchronous speed r/min |

Outline installation dimension | Pump outlet size | ||||||||

| L | L1 | L2 | B | H | H1 | D | D0 | N-D0 | D1 | |||||||

| 50WQ(D)10-10-0.75S | 10 | 10 | 0.75 | 220/380 | 60 | 3000 | 349 | 140 | 246 | 212 | 492 | 110 | φ50 | φ110 | 4-φ14 | φ140 |

| 65WQ(D)15-6-0.75S | 15 | 6 | 0.75 | 220/380 | 65 | 3000 | 353 | 140 | 246 | 212 | 492 | 110 | Φ 65 | Φ 130 | 4-φ14 | φ160 |

| 50WQ(D)15-10-1.1S | 15 | 10 | 1.1 | 220/380 | 50 | 3000 | 353 | 140 | 246 | 212 | 522 | 110 | φ50 | φ110 | 4-φ14 | φ140 |

| 65WQ(D)25-7-1.1S | 25 | 7 | 1.1 | 220/380 | 65 | 3000 | 353 | 140 | 246 | 212 | 522 | 110 | Φ 65 | Φ 130 | 4-φ14 | φ160 |

| 50WQ(D)15-15-1.5S | 15 | 15 | 1.5 | 220/380 | 50 | 3000 | 353 | 140 | 246 | 212 | 522 | 110 | φ50 | φ110 | 4-φ14 | φ140 |

| 65WQ(D)25-10-1.5S | 25 | 10 | 1.5 | 220/380 | 55 | 3000 | 353 | 140 | 246 | 212 | 522 | 110 | Φ 65 | Φ 130 | 4-φ14 | φ160 |

| 80WQ(D)40-6-1.5S | 40 | 6 | 1.5 | 220/380 | 30 | 3000 | 411 | 155 | 261 | 207 | 539 | 119 | Φ 80 | Φ 150 | 4-φ17.5 | Φ 190 |

| 50WQ(D)15-20-2.2S | 15 | 20 | 2.2 | 220/380 | 50 | 3000 | 369 | 158 | 266 | 217 | 558 | 118 | φ50 | φ110 | 4-φ14 | φ140 |

| 65WQ(D)25-15-2.2S | 25 | 15 | 2.2 | 220/380 | 65 | 3000 | 385 | 161 | 267 | 220 | 557 | 119 | Φ 65 | Φ 130 | 4-φ14 | φ160 |

| 80WQ(D)40-9-2.2S | 40 | 9 | 2.2 | 220/380 | 80 | 3000 | 431 | 169 | 283 | 228 | 564 | 122 | Φ 80 | Φ 150 | 4-φ17.5 | Φ 190 |

| 100WQ(D)50-7-2.2S | 50 | 7 | 2.2 | 220/380 | 100 | 3000 | 480 | 180 | 302 | 244 | 579 | 129 | Φ 100 | φ170 | 4-φ17.5 | φ210 |

| 50WQ15-25-3S | 15 | 25 | 3 | 380 | 50 | 3000 | 389 | 168 | 286 | 236 | 575 | 117 | φ50 | φ110 | 4-φ14 | φ140 |

| 65WQ25-20-3S | 25 | 20 | 3 | 380 | 65 | 3000 | 406 | 169 | 288 | 238 | 580 | 119 | Φ 65 | Φ 130 | 4-φ14 | φ160 |

| 80WQ40-15-3S | 40 | 15 | 3 | 380 | 80 | 3000 | 448 | 176 | 300 | 255 | 588 | 121 | Φ 80 | Φ 150 | 4-φ17.5 | Φ 190 |

| 100WQ50-10-3S | 50 | 10 | 3 | 380 | 100 | 3000 | 502 | 191 | 324 | 265 | 605 | 129 | Φ 100 | φ170 | 4-φ17.5 | φ210 |

| 50WQ15-32-4S | 15 | 32 | 4 | 380 | 50 | 3000 | 389 | 168 | 286 | 236 | 600 | 117 | φ50 | φ110 | 4-φ14 | φ140 |

| 65WQ25-25-4S | 25 | 25 | 4 | 380 | 65 | 3000 | 406 | 169 | 288 | 238 | 605 | 119 | Φ 65 | Φ 130 | 4-φ14 | φ160 |

| 80WQ40-18-4S | 40 | 18 | 4 | 380 | 80 | 3000 | 448 | 176 | 300 | 255 | 613 | 121 | Φ 80 | Φ 150 | 4-φ17.5 | Φ 190 |

| 100WQ50-15-4S | 50 | 15 | 4 | 380 | 100 | 3000 | 502 | 191 | 324 | 266 | 630 | 129 | Φ 100 | φ170 | 4-φ17.5 | φ210 |

| 50WQ20-32-5.5S | 20 | 32 | 5.5 | 380 | 50 | 3000 | 425 | 189 | 322 | 266 | 689 | 125 | φ50 | φ110 | 4-φ14 | φ140 |

| 65WQ30-25-5.5S | 30 | 25 | 5.5 | 380 | 65 | 3000 | 440 | 189 | 322 | 284 | 691 | 126 | Φ 65 | Φ 130 | 4-φ14 | φ160 |

| 80WQ50-18-5.5S | 50 | 18 | 5.5 | 380 | 80 | 3000 | 490 | 200 | 342 | 285 | 714 | 139 | Φ 80 | Φ 150 | 4-φ17.5 | Φ 190 |

| 100WQ80-10-5.5S | 80 | 10 | 5.5 | 380 | 100 | 3000 | 528 | 202 | 350 | 295 | 722 | 141 | Φ 100 | φ170 | 4-φ17.5 | φ210 |

| 150WQ100-7-5.5S | 100 | 7 | 5.5 | 380 | 150 | 3000 | 608 | 225 | 379 | 308 | 733 | 150 | Φ 150 | φ225 | 8-φ17.5 | φ265 |

| 50WQ20-40-7.5S | 20 | 40 | 7.5 | 380 | 50 | 3000 | 437 | 189 | 334 | 289 | 722 | 158 | φ50 | φ110 | 4-φ14 | φ140 |

| 65WQ30-32-7.5S | 30 | 32 | 7.5 | 380 | 65 | 3000 | 462 | 199 | 344 | 289 | 735 | 166 | Φ 65 | Φ 130 | 4-φ14 | φ160 |

| 80WQ45-22-7.5S | 45 | 22 | 7.5 | 380 | 80 | 3000 | 493 | 200 | 345 | 289 | 747 | 172 | Φ 80 | Φ 150 | 4-φ17.5 | Φ 190 |

| 100WQ80-15-7.5S | 80 | 5 | 7.5 | 380 | 100 | 3000 | 528 | 202 | 50 | 295 | 772 | 174 | φ100 | φ170 | 4-φ17.5 | φ210 |

| 150WQ100-10-7.5S | 100 | 0 | 7.5 | 380 | 150 | 3000 | 608 | 225 | 379 | 308 | 755 | 183 | Φ 150 | φ225 | 8-φ17.5 | φ265 |

| 65WQ30-50-11S | 30 | 50 | 11 | 380 | 65 | 3000 | 480 | 218 | 362 | 288 | 927 | 180 | Φ 65 | Φ 130 | 4-φ14 | φ160 |

| 80WQ45-42-11S | 45 | 42 | 11 | 380 | 80 | 3000 | 512 | 220 | 364 | 288 | 933 | 186 | Φ 80 | Φ 150 | 4-φ17.5 | Φ 190 |

| 100WQ100-20-11S | 100 | 20 | 11 | 380 | 100 | 3000 | 528 | 202 | 349 | 295 | 924 | 179 | φ100 | φ170 | 4-φ17.5 | φ210 |

| 150WQ180-11-11S | 180 | 11 | 11 | 380 | 150 | 3000 | 608 | 224 | 379 | 308 | 935 | 183 | Φ 150 | φ225 | 8-φ17.5 | φ265 |

| 65WQ30-60-1 5S | 30 | 50 | 15 | 380 | 65 | 3000 | 480 | 218 | 362 | 288 | 927 | 180 | Φ 65 | Φ 130 | 4-ψ 14 | φ160 |

| 80WQ45-52-15S | 45 | 2 | 15 | 380 | 80 | 3000 | 512 | 220 | 364 | 288 | 933 | 186 | Φ 80 | Φ 150 | 4-φ17.5 | Φ 190 |

| 100WQ100-25-15S | 100 | 25 | 15 | 380 | 100 | 3000 | 528 | 202 | 349 | 295 | 924 | 179 | φ100 | φ170 | 4-φ17.5 | φ210 |

| 150WQ180-15-15S | 180 | 5 | 15 | 380 | 150 | 3000 | 608 | 224 | 379 | 308 | 935 | 183 | Φ 150 | φ225 | 8-φ17.5 | φ265 |

Previous

None

Next